In the ongoing upgrade of car braking systems, ceramic brake pads have become a popular choice for many car owners due to their 'high-temperature resistance' and 'low noise' features. However, when driving through the humid and hot southern rainy season, the harsh cold northern snowfields, or the dry northwest deserts, a critical question arises: Can ceramic brake pads truly perform consistently across all seasons and climates? To answer this question, a thorough analysis of the material's properties and its environmental adaptability is necessary.

The basic adaptability determined by material genes

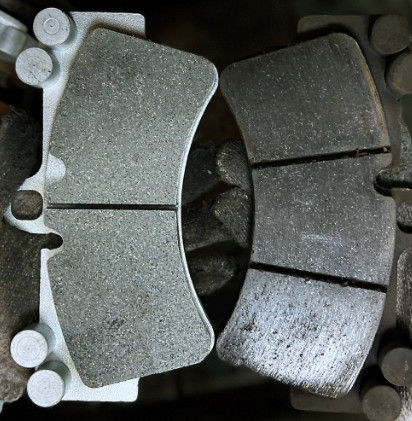

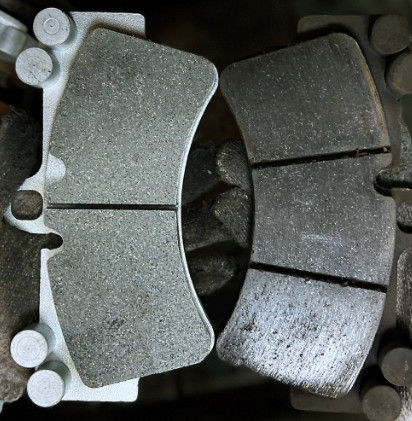

The advantages of ceramic brake pads stem from their unique material composition. These pads are made with a core of ceramic fibers, such as alumina and aluminum silicate, along with non-metallic fillers like aramid fibers and graphite, and bonded with high-temperature resistant resin. This composite structure gives ceramic brake pads superior climate adaptability compared to traditional metal brake pads. In extremely cold conditions, ordinary semi-metal brake pads often experience a sharp drop in friction coefficient due to the cold contraction of their metal components, leading to 'soft braking.' However, ceramic materials have a thermal expansion coefficient about one-third that of steel. For instance, in the-30℃ winter in Northeast China, the friction coefficient of ceramic brake pads fluctuates by less than 5%, maintaining stable braking performance. This stability is attributed to the structural integrity of ceramic fibers at low temperatures.

When faced with high temperatures, ceramic materials demonstrate superior thermal stability. Traditional asbestos brake pads experience a sharp decline in friction performance when the temperature exceeds 200℃ due to the decomposition of organic components, whereas ceramic brake pads can maintain their performance at temperatures above 600℃. During summer mountain climbs, when the brake disc temperature reaches 400℃, the friction coefficient of ceramic brake pads remains within the ideal range of 0.35-0.40, which is about 30% higher than that of metal brake pads. This high-temperature resistance is not only due to the high melting point of ceramic fibers but also to its unique porous structure. These micron-level pores form an air insulation layer at high temperatures, effectively preventing heat from penetrating the brake pad.

Performance boundaries in complex climates

Despite their broad adaptability, ceramic brake pads still face performance limitations in extreme weather conditions. In high-humidity environments, such as the plum rain season in southern regions or coastal areas, the hydrophilic nature of ceramic brake pads can cause temporary performance fluctuations. When moisture penetrates the micro-pores on the brake pad surface, it forms a 'water film effect' during braking, increasing the initial braking distance by about 10%-15%. However, this effect is transient; as heat is generated during braking, the moisture evaporates quickly, and the friction coefficient typically returns to normal after 2-3 braking cycles.

In harsh road conditions with high dust and gravel, the self-cleaning capability of ceramic brake pads faces significant challenges. Although their hardness (around 60-70HRA) is higher than that of conventional brake pads, which helps reduce the generation of grinding debris, sand particles embedded in the friction surface can cause a 'grinding effect.' Long-term tests in the Gobi Desert region of Northwest China show that after 10,000 kilometers of driving, the wear on ceramic brake pads increases by about 20% compared to regular conditions, and the incidence of braking noise rises to 15%. This is because sand particles damage the smooth friction layer on the brake pad surface, leading to uneven pressure distribution, which necessitates more frequent cleaning and maintenance of the braking system.

Your message must be between 20-3,000 characters!

Please check your E-mail!

Your message must be between 20-3,000 characters!

Please check your E-mail!